Every component part of our CAD/CAM software is a professional tool in itself – yet simple without previous experience! In the first step your geometric drawings are created using our CAD module, the Sketcher, or you can import any popular drawing format for example from your customer’s design. Next these drawings are automatically converted by our CAM module to files your cutting machine can understand. The drawings are given ‘technology data’. In this process, cncCUT will suggest the best lead-in points and cutting paths to you, however you retain the power to adjust manually as you see fit. Finally your new parts can be nested efficiently on your sheet metal, and the NC code for your machine created automatically.

A Selection Of Our Functionality:

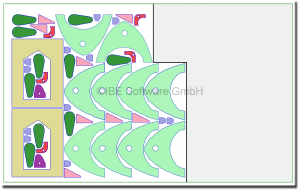

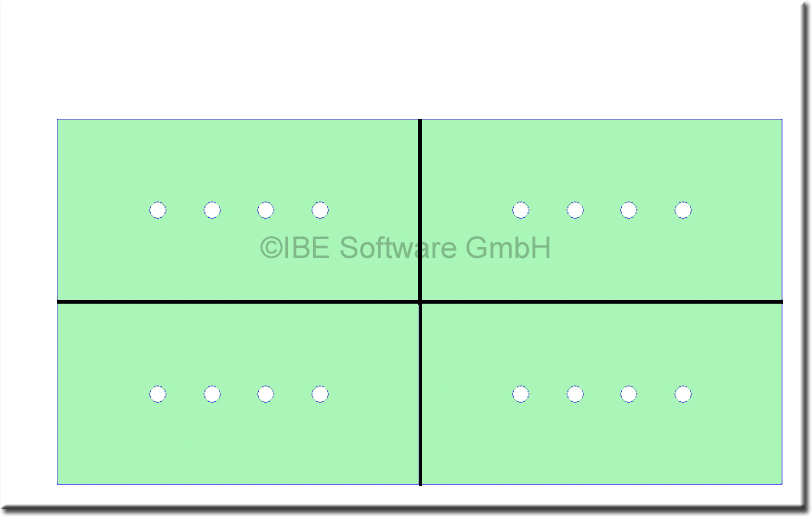

Offcut Sheets And Offcut Grids:

- Convert a nesting plan into an offcut grid.

- Offcuts with true-shape cuts.

- Separate into multiple offcuts.

- Label your offcuts.

- One-click offcut creation.

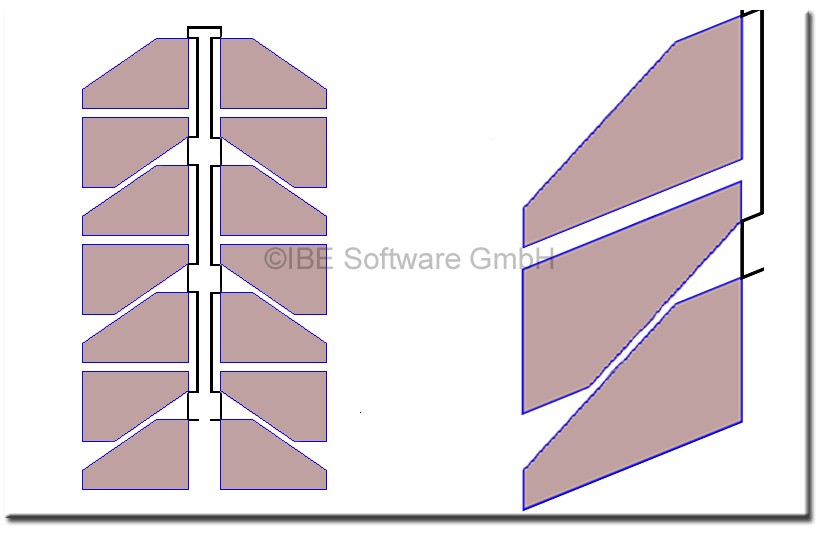

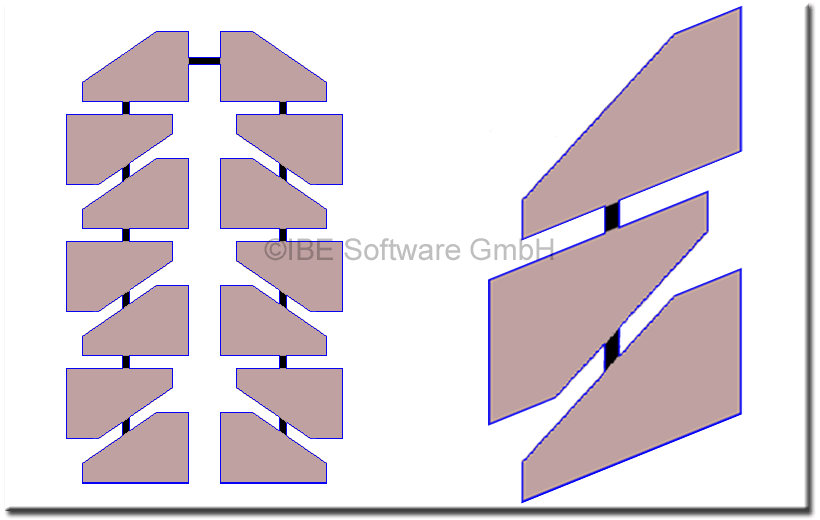

Common Separating Cuts:

- Automatic layout of identical parts.

- cncCUT suggests various permutations.

- The cutting offset is considered at all times.

- True-shape nesting allows parts with and without separating cuts to be nested.

Chain Cuts:

- Chain cuts combine lead-ins and lead-outs.

- Multiple contours can be processed in one cut;

- Time-consuming multiple pre-drilling is avoided.

Bridge Cuts:

- Bridge Cuts combine parts using webs, so that bridges occur.

- Time-consuming multiple pre-drilling is avoided.

Edit And Repair Faulty Drawings

Immediate repairs of:

- Open contours.

- Elements unconnected to other elements.

- Circles and arcs with identical centers and radii.

- Unjoined arcs or vectors, which join at 180 degrees (tangential connections).