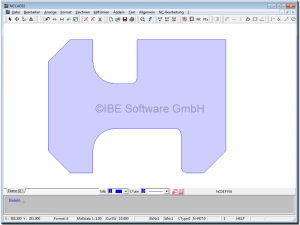

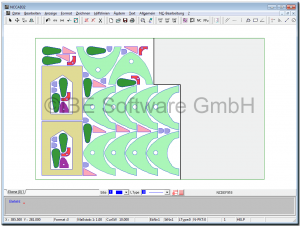

ncCAD32’s CAM module offers automated and manual program creation. You have full control and flexibility. Cutting paths are created with a click, and can be fine-tuned to meet your design. Changes made to one workpiece can be copied over to another, or applied automatically to all workpieces. The focus is always on optimization of cutting paths! You can enter technology data for each machine, material type and thickness, and adjust any time. The technology data tables contain parameters such as cutting quality, speed, and settings concerning marking texts.

Your Advantages Summarized:

- Automatic creation of technology data.

- Material type and thickness specific technology data tables.

- Precise time calculations.

- Semi and fully automatic multi-torch operation.

- True-shape and manual nesting functionality.

- Loops, bevels and fillet corners.

- Save time with common separating cuts.

- Lead-in management (dynamic lead-ins, corner lead-ins, one-off lead-ins…)

- Add micro webbing, cutting bridges and chain cuts.

- Beveled edges on machines with tilting cutting heads.

Also included are many more important functions such as offcut sheet creation and chain cuts. Our customizable macros round out the ncCAD32 package.

Furthermore we offer a great service pallet to complement ncCAD32.